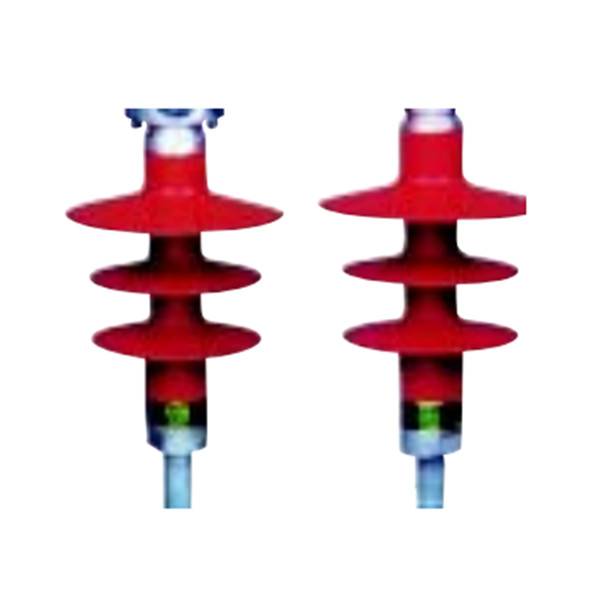

2020 wholesale price 120KV High Voltage - Insulator Good anti-strike, astigmatic and anti-blast capability composite insulator for electrical supply – Hawai

2020 wholesale price 120KV High Voltage - Insulator Good anti-strike, astigmatic and anti-blast capability composite insulator for electrical supply – Hawai Detail:

With the developing of power electric industry, composite insulator of organic insulator material has been popular for its excellent power electric capability. It has token the place of traditional ceramic insulator. Umbrella- -shaped compos-ite insulator is made of silicon rubber to sure insulator outside. High intensity epoxy club supplies internal insula-tor and bearing mechanic load, This production adopts silicon rubber umbrella-shaped mould, core club and metal clip pressure connection craftwork, improving reliability,And it has merit as following:

1. Advanced electric capacity and strong dirty proof. The silicon rubber with strong bibulous power improve the level of dirty proof . The voltage of wet proof and dirty proof is equal to 2-2.5 times of ceramic insulator. It reduces dirty incident and improve economic and reliability of network,

2. Composite insulator has internal bearing epoxy of high tensile strength, 2-3 times to normal steel and 8- 10 times to high intensity, so improve greatly mechanic capability.

3. adopts advanced pressure connection craftwork in bor-der and mandrill to assure reliable mechanic intensity.

4. Silicon rubble has excellent resist high and low temperature, season, old and electron rot capability, And solid frame with epoxy club, it is sure of no damp and needn’t clear.

5. Small volume, light weight( 1/4- 1/8as to same voltage),adopting standard ball and socket constructor for easy transport.

6. Good anti-strike, astigmatic and anti-blast capability.

Product detail pictures:

Related Product Guide:

We insist on offering premium quality creation with very good company concept, honest product sales along with the finest and fast assistance. it will bring you not only the premium quality item and huge profit, but the most significant is to occupy the endless market for 2020 wholesale price 120KV High Voltage - Insulator Good anti-strike, astigmatic and anti-blast capability composite insulator for electrical supply – Hawai , The product will supply to all over the world, such as: Serbia, Peru, Peru, We are committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.